Services

Our activity is structured in several independent but interconnected areas. We can carry out targeted tasks related to a single sector or take charge of operations that encompass broader and more complex processes, to be evaluated with the client on a case-by-case basis.

Vai a

Engineering

The conceptualization phase is followed by the preliminary feasibility study, which consists of several points:

- Macro feasibility

- Vehicle volumetries

- Vehicle ergonomics

- Contactability and accessibility

- Assembly sequence

- Breakdown of elements

- Lighting

- C B A Class surface

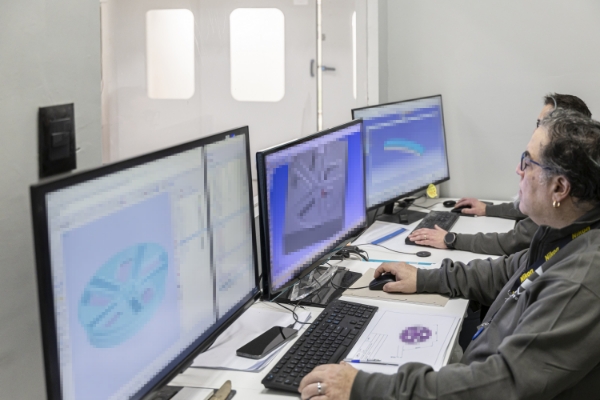

- CAS CAD CAM

The team uses various software to produce the 3D models: Rhinoceros, Catia v5, UG Nx, PTC Creo, ALIAS, ICEM.

Milling

By 2025, GMA ProtoLab is planning to get bigger acquiring some new milling machines and new spaces to enforce the existing plant and in addition to the original one, dedicated to mini series production.

The renewing is giving GMA ProtoLab a complete new shape: arranged over 5000 mq we have a main big milling department with 5 CNC machines and a separate area for other 3 CNC machines devoted to iron ore milling. Three completely renewed mounting boxes and two separate twin areas into the painting department.

Everything is built up to guarantee contemporary machining compliant with quality and privacy standards.

Our Milling department can count on 8 CNC machines:

- 2 Poseidon (8000x4000 h 2500 and h 2000), 2019 and new

- MX5 (7000x3500 h 2000), new

- Ares (2500x1600 h 1000), 2017

- Antares (3600x1600 h 1600), 2010

- 2 Doosan (600x2000 h 400), 2007 - Iron machining only

- Rambaudi (400x400 h 400), 2000 - Iron machining only

Modelling

In the modeling department there are 3 Boxes with 3 independent plateaux, equipped with the latest generation of measuring instruments.

Each area has independent access in total security with its own access badges for authorized employees only. We make all kinds of mock-ups in-house, exterior models, Interior, opening doors, see through and master models.

Mounting Department

Each mounting box is equipped with specific hand tools and with:

- Graduated Gauges (and relative plateau), 2000

- Real Time Point Inspector, 2024

- 3D Scanning, 2024

- Large control wall screen for viewing data and surveys in real time, 2024

Prototype Construction

Gma ProtoLab offers a complete service for the realization of concept cars and running prototypes. Our technicians are able to suggest and offer innovative and technological solutions with the sole purpose of fulfilling the client’s wishes while respecting definite time and costs.

Painting

The company was born from extensive

experience in painting, which has enabled it

to organize and optimize the production

lay-out and process at all stages, always

in absolute safety for the customer.

Preparation Area

GMA ProtoLab has 3 areas dedicated to preparing products for painting where they are placed in absolute security and secrecy, with secure and independent access.

Painting Area

The process goes through several stages, thanks to 4 dedicated ovens and 3 preparation rooms.

The goal is to achieve an optimal and durable paint job, guaranteed by the highest quality machinery, technologies and paints that can enhance the aesthetics of the vehicle.

The coloring of the vehicle is done after sharing with the customer several color tests on samples.

The renewed painting department is organized into two twin areas that let us guarantee a contemporary machining, preserving each client privacy. It is equipped as follow:

- 2 Oven TERMOMECCANICA, 2022

- 2 Oven BLOWTHERM, 2000

- 3 Preparation Area TERMOMECCANICA, 2022

- 2 Polishing areas with light tunnel specific for painting quality check

Each machine is compliant with industry 4.0.

Finishing Area

Dedicated post-painting finishing department with dedicated boxes equipped with control lights where optical inspections and finishing and polishing operations are carried out.

Lighting and electronics

Not only chassis and body, our design engineers deal with every aspect inherent in the specific vehicle to be manufactured and assembled.

An expertise that starts from UX design and is based on an approach that puts the user at the center, and constantly questions usability and human-machine interaction, preliminary to the subsequent prototype realization. A key role is played by the lighting system, both external and internal: we are able to make both front and rear lights. Automotive lights are complex devices: they consist of metal reflectors, bulb or LED light sources, embossed and transparent elements such as polycarbonate lenses, which give the component a brilliant appearance. Along with the lights come the vehicle’s electronics, the nervous system that now regulates every element and process of vehicle operation and driving experience.

Color and setting up

The starting point of our professional approach is conducting an in-depth trend and competitive analysis to intercept market needs and anticipate our clients’ demands.

This preliminary step allows us to set solid foundations for the development of new product strategies, proposing innovative and distinctive solutions that stand out within an already highly competitive landscape. A key role involves the proposal of new directions for colors, materials and finishes (CMF), with a particular focus on sustainability, now an essential element. Design is developed in parallel with styling, from the research stage to the development stage, ensuring aesthetic and functional consistency. In this process, great care is taken in defining specifications for textures, graphics and materials, to ensure a strong and recognizable visual identity.

Building synergy with brands is essential, working closely with the development, product marketing and production departments. Cooperation with suppliers is equally strategic to transform ideas into feasible solutions, optimizing time and costs, and maintaining high quality standards.

Tailor-made

Within the company there is a team of design engineers dedicated to the design of finite elements to produce a one-off model useful for testing the vehicle itself.

One-Off

It sounds like GMA ProtoLab is all about offering a highly personalized and exceptional vehicle creation experience! Customizing every component, along with the skill and commitment of expert technicians, shows a deep level of craftsmanship.

Are we focused on specific types of vehicles or is it more about high-end, luxury cars in general? It’d be cool to hear more about the kinds of customization options we offer!

Additive Manufacturing

The evolution of the car, especially with the transition to the electric motor, represents a real revolution not only in propulsion, but also in engineering and component design.

The change to the electric vehicle requires a thorough rethinking of all aspects of car construction, including materials, design, and manufacturing processes.

In this context, additive manufacturing (3D printing) is proving to be a key ally, not only for rapid prototyping but also for the production of final components. Indeed, 3D printing allows great freedom in shapes, enabling the design of complex geometries that would otherwise be difficult to achieve with traditional manufacturing techniques. Not only does this approach offer opportunities in terms of design optimization, but it also enables component weight reduction and improved structural performance, a key feature for electric vehicles, where energy efficiency is a crucial aspect.

One-Off and Special Color painting

Painting is the most tangible element of the process, which is why it must be of the highest quality and perfectly meet the customer’s needs, for each and every one.

We are partners with our clients: this is our philosophy.

Highly-experienced team

ONE-OFF AND SPECIAL COLOR PAINTING

The staff consists of as many as 24 carefully selected professionals who are also highly specialized in the control and rectification of surfaces and theoretical elements, to precede the phase inherent in product painting.

The many years of collaboration with various car manufacturers, such as Stellantis Group (for special color management), Maserati and Stellantis style center, who cyclically renew their trust by entrusting us with their models and prototypes (static and dynamic), is a great source of pride for us.

Specializations:

- Painting of production bodies and carbon fiber components

- Application of liveries and similar

Production complex

ONE-OFF AND SPECIAL COLOR PAINTING

Processing takes place in a single covered area of 6,000 square meters, scrupulously subdivided to accommodate the progressive needs of the production process.

It is structured, right from the design stage, to meet the customer’s needs for confidentiality.

The complex consists of:

- 5 areas set up for preparation for machining and finishing on manufactured goods;

- double manual painting line;

- 8 painting and drying ovens;

- triple-stage painting booth with a maximum operating temperature of 90 degrees;

- polishing plant, consisting of three booths equipped in turn with a high-tech vacuum and lighting system;

- quality control box, equipped with high-tech lighting for painting quality control with special attention to color-matching.

Processes

ONE-OFF AND SPECIAL COLOR PAINTING

We work on a variety of product types: prototypes in metal, plastic or composite materials.

Expertise in finishing operations and assembly of external and internal finishing (with the support of a specialized saddler).

We also have an advanced in-house laboratory for color research that enables the management of coatings with special surface effects, such as:

- metallurgical colors;

- chrome effect colors;

- ink colors;

- laboratory for adhesion tests when new and after immersion according to standard 2409/4624.

Transport infrastructure

Design and Production for Railway and Aeronautical Infrastructure

Our company takes care of everything from design to prototyping and industrial production of components and systems by offering tailor-made solutions of functional prototypes up to series production.

Thanks to a multidisciplinary team and the use of the latest CAD/CAM and additive manufacturing technologies, and state-of-the-art CNC milling machines, we are able to support every stage of the product and component life cycle.

Our mission is to innovate transport infrastructures through technical expertise, design flexibility, and a strong focus on industry regulations.

- structures and components for railway infrastructure

- signalling and safety systems

- infrastructures for airports and flight support facilities

- integrated solutions for efficiency and operational sustainability